Woodworking is an art form that requires precision, creativity, and the right tools. Among these tools, table saw blades stand out as essential instruments for any woodworker’s arsenal. These circular cutting tools are the heartbeat of the woodworking shop, enabling craftsmen to transform raw materials into works of art with unparalleled accuracy and efficiency.

Imagine a table saw without a blade—it’s like a painter without a brush or a chef without a knife. Table saw blades are the workhorses of the woodworking world, tirelessly slicing through wood, plastic, metal, and more, with each rotation delivering clean, precise cuts that form the foundation of countless projects.

But table saw blades are not one-size-fits-all; they come in a variety of types, sizes, and materials, each tailored to specific cutting tasks and materials. Understanding the nuances of these blades is crucial for woodworkers seeking to elevate their craft and achieve professional-quality results.

In this comprehensive guide, we’ll delve into the intricacies of table saw blades, exploring the different types available, the optimal sizes for various applications, and the materials used in their construction.

By the end of this journey, you’ll have a newfound appreciation for these unsung heroes of the workshop and the knowledge to choose the perfect blade for your next woodworking endeavor. So, let’s roll up our sleeves, sharpen our wits, and embark on a journey into the world of table saw blades.

Understanding Table Saw Blades

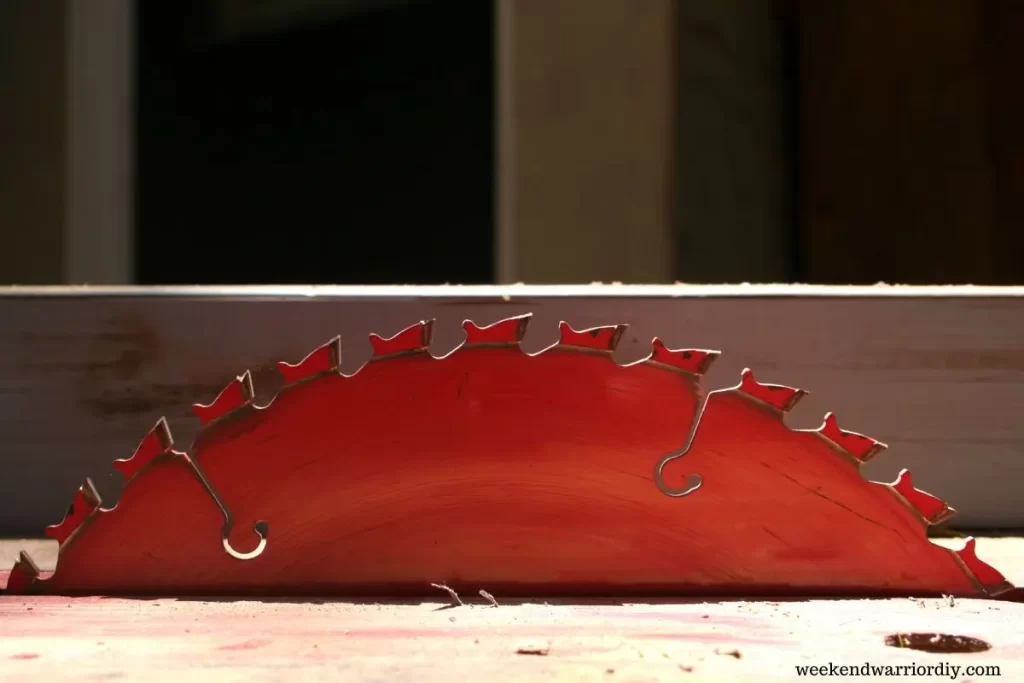

When it comes to table saw blades, versatility is the name of the game. Woodworkers rely on these essential tools to tackle a wide range of cutting tasks, from slicing through hardwoods to crafting intricate joinery. Understanding the different types of table saw blades is key to achieving the desired results in your woodworking projects.

Rip Blades

Imagine the grain of a piece of wood as a series of parallel lines stretching from end to end. Rip blades are specifically engineered to slice along these grain lines, making them the go-to choice for cutting boards to width or length.

With their aggressive tooth geometry and large gullets, rip blades excel at hogging out material quickly and efficiently, resulting in smooth, straight cuts that follow the natural direction of the wood fibers.

Crosscut Blades:

In contrast to rip blades, crosscut blades are designed to cut across the grain of the wood, traversing those parallel lines with finesse and precision. These blades feature a different tooth configuration, typically with a higher tooth count and alternate top bevel (ATB) or alternating top bevel with raker (ATBR) tooth patterns.

This tooth design, combined with smaller gullets, ensures clean, splinter-free cuts that leave behind a glass-smooth surface ready for finishing.

Combination Blades:

For woodworkers who demand versatility without sacrificing performance, combination blades offer the best of both worlds. These hybrid blades feature a combination of rip and crosscut tooth configurations, allowing them to tackle a wide range of cutting tasks with ease.

Whether you’re ripping boards to width or crosscutting delicate trim pieces, a combination blade can handle it all without skipping a beat, making it the perfect choice for hobbyists and professionals alike.

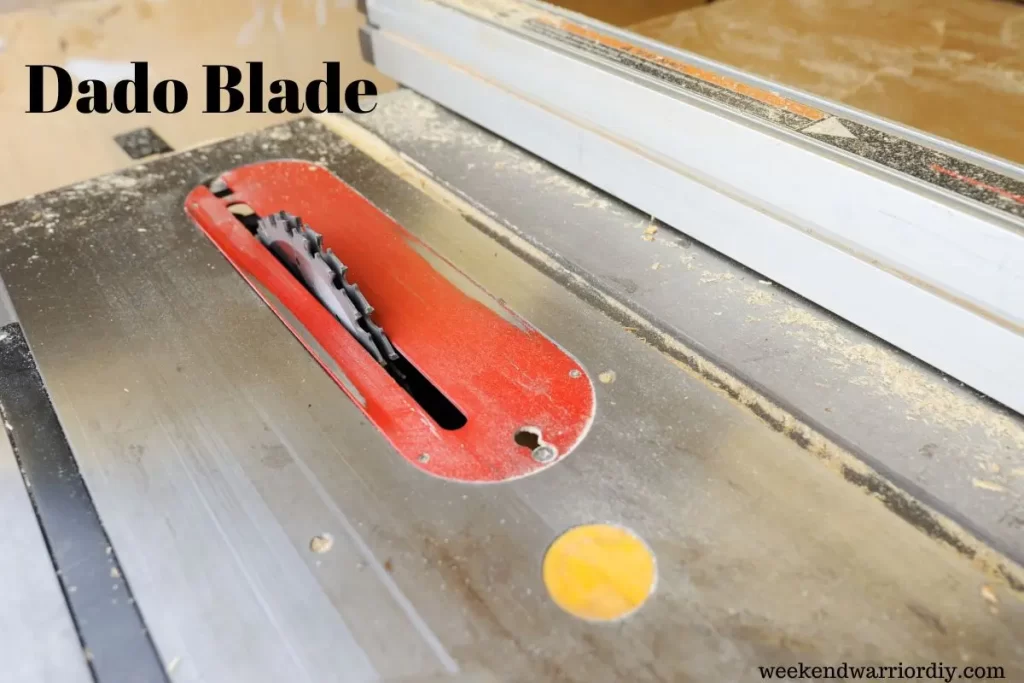

Dado Blades:

When it comes to creating precise joinery such as dadoes, grooves, and rabbets, dado blades reign supreme. These specialized blades feature multiple cutting teeth stacked together on a single arbor, allowing them to remove material in width rather than depth.

By adjusting the blade’s width, woodworkers can achieve custom-sized dadoes and grooves to accommodate various joinery techniques, making dado blades an indispensable tool in the woodworking arsenal.

In summary, the types of table saw blades available cater to a diverse range of cutting tasks and woodworking applications. Whether you’re ripping, crosscutting, or joinery-making, there’s a blade designed to meet your needs and deliver exceptional results.

By understanding the strengths and limitations of each type of blade, woodworkers can confidently select the right tool for the job and unleash their creativity in the workshop.

Sizes of Table Saw Blades

Table saw blades, like tools in any craftsman’s arsenal, come in a variety of sizes, each tailored to specific cutting needs. The most common diameters for table saw blades are 8-inch, 10-inch, and 12-inch. The size of the blade plays a crucial role in the depth and precision of the cuts it can make.

Smaller blades, such as the 8-inch variety, are often favored for portable or benchtop table saws, where space and maneuverability are limited. These blades are ideal for lighter-duty tasks and are commonly used in hobbyist workshops or for smaller-scale projects.

The 10-inch blade is the workhorse of the table saw world, found in most contractor and cabinet table saws. Its versatility makes it suitable for a wide range of cutting tasks, from ripping and crosscutting to bevel cuts and dadoes. With a larger diameter than the 8-inch blade, the 10-inch blade offers increased cutting depth and precision, making it a favorite among professional woodworkers.

For those tackling heavy-duty projects or working with thick stock, the 12-inch blade is the tool of choice. With its larger diameter, this blade can slice through dense hardwoods and thick materials with ease, delivering clean, accurate cuts even in challenging conditions.

While less common than the 8-inch and 10-inch varieties, the 12-inch blade is indispensable for serious woodworkers seeking maximum cutting capacity.

In summary, the size of the table saw blade directly impacts its cutting capabilities, with larger blades offering greater depth and precision for tackling larger projects and thicker materials.

Materials Used in Table Saw Blades

Just as there are different strokes for different folks, there are different materials for different blades. Each material used in table saw blades brings its own set of strengths and characteristics to the table, allowing woodworkers to tailor their tools to the task at hand.

Carbide-Tipped Blades

For woodworkers seeking durability and longevity, carbide-tipped blades are the gold standard. These blades feature carbide teeth brazed onto a steel body, offering exceptional hardness and wear resistance.

Ideal for cutting hardwoods, abrasive materials, and tough composite materials, carbide-tipped blades maintain their sharpness longer than traditional steel blades, reducing the need for frequent sharpening and replacement.

High-Speed Steel Blades

Affordable and versatile, high-speed steel blades are the jack-of-all-trades in the woodworking world. Made from hardened steel alloy, these blades offer excellent durability and cutting performance across a wide range of materials.

Whether you’re tackling softwoods, hardwoods, or engineered materials, high-speed steel blades deliver reliable results without breaking the bank.

Diamond Blades

When it comes to cutting hard materials like tile, stone, and concrete, diamond blades are the cutting-edge solution. These blades feature industrial-grade diamonds bonded to a metal matrix, offering unparalleled hardness and abrasion resistance.

With their ability to slice through even the toughest materials with ease, diamond blades are essential tools for masonry work, tile installation, and concrete cutting projects.

In conclusion, the choice of material for your table saw blade depends on the specific requirements of your project, with each material offering unique benefits in terms of durability, cutting performance, and versatility.

Whether you’re cutting wood, metal, or masonry, there’s a table saw blade out there suited to your needs, ready to help you tackle any task with precision and confidence.

Choosing the Right Blade for the Job

Selecting the perfect table saw blade is akin to choosing the right tool for a specific task—it requires careful consideration of various factors to ensure optimal results. First and foremost, take into account the material you’ll be cutting.

Different materials, whether it’s hardwood, softwood, plywood, or laminate, require different blade types and configurations for the best performance. Next, consider the desired cut quality. Are you aiming for smooth, splinter-free cuts, or are you willing to sacrifice a bit of precision for speed?

Lastly, don’t forget about budget constraints. While premium blades may offer superior performance, there are plenty of budget-friendly options available that provide decent results without breaking the bank.

By matching the blade type, size, and material to the specific requirements of your woodworking project, you’ll ensure that every cut is made with precision and confidence.

Maintenance and Care

Just like any other tool in your workshop, table saw blades require regular maintenance to perform at their best. To prolong their lifespan and maintain optimal cutting performance, it’s essential to keep them clean and sharp.

Regularly inspect your blades for signs of damage or dullness and invest in a quality blade cleaning solution to remove built-up pitch, resin, and other debris. When it comes to sharpening, there are several methods available, from manual sharpening tools to professional blade sharpening services.

By taking the time to properly care for your blades, you’ll not only save money on replacements but also ensure safer and more efficient cutting operations in the long run.

Safety Precautions

Safety should always be the top priority when working with table saw blades. Before starting any cutting operation, be sure to wear appropriate protective gear, including safety glasses, hearing protection, and, if necessary, a dust mask.

Keep your work area clean and free of clutter to prevent accidents, and always follow manufacturer guidelines for blade installation and operation.

Never use damaged or improperly installed blades, as they can lead to kickbacks, binding, and other dangerous situations.

By prioritizing safety in your woodworking practices, you’ll create a safer and more productive work environment for yourself and those around you.

Popular Brands and Recommendations

When it comes to table saw blades, quality matters. Fortunately, there are several reputable brands known for producing high-quality blades that deliver exceptional performance and durability.

Brands such as Freud, Diablo, and Forrest have built a solid reputation among woodworkers for their precision-engineered blades that consistently produce clean, accurate cuts. That being said if you are just a hobbyist working out of your garage making the odd thing on the weekend, then just about any brand is just fine.

Before making a purchase, be sure to read customer reviews and seek out expert recommendations to ensure that you’re investing in a blade that meets your specific needs and expectations.

Surprisingly Amazon has many high grade saw blades available. You can save money shopping on Amazon as well and with next day delivery you can start cutting right away.

Affiliate Link: Check out Amazons Table Saw Blades Here!

Budget-Friendly Options

Woodworking doesn’t have to break the bank, and that includes your choice of table saw blades. While premium blades may offer superior performance and longevity, there are plenty of budget-friendly options available that provide decent results at a fraction of the cost.

Look for blades from reputable brands that offer a balance between cost and quality, and don’t be afraid to experiment with different blade types and configurations to find the perfect fit for your projects.

Advanced Techniques and Specialized Blades

As your skills and confidence grow in the workshop, so too will your desire to explore advanced cutting techniques and specialized blades. Whether you’re experimenting with bevel cuts, dado cuts, or intricate joinery, there’s a specialized blade out there designed to help you achieve your woodworking goals.

From thin-kerf blades for fine detail work to dado sets for precision joinery, the possibilities are endless. Don’t be afraid to push the boundaries of your creativity and explore new techniques with the help of specialized blades tailored to your specific needs.

Comparison Between Different Blades

With so many table saw blades on the market, choosing the right one can feel like a daunting task.

To help narrow down your options, take the time to compare the features and performance of various blades based on factors such as tooth count, tooth configuration, and material compatibility.

Consider how each blade type suits your cutting needs and preferences, and don’t hesitate to reach out to fellow woodworkers or industry experts for advice and recommendations.

By conducting thorough research and comparing your options, you’ll be better equipped to make an informed purchasing decision that meets your woodworking needs and budget.

User Reviews and Testimonials

When it comes to choosing the right table saw blade, there’s no substitute for real-world experience. Before making a purchase, take the time to read user reviews and testimonials from fellow woodworkers who have firsthand experience with the blades you’re considering.

Pay attention to feedback on cutting performance, durability, and overall satisfaction to gauge whether a particular blade meets your expectations.

Additionally, consider joining online woodworking communities or forums where you can ask for recommendations and advice from experienced woodworkers who can offer valuable insights and guidance.

Future Trends in Table Saw Blades

As technology continues to evolve, so too will the design and performance of table saw blades. In the coming years, expect to see innovations in blade materials, cutting geometries, and specialized coatings that enhance cutting performance and durability.

From advanced carbide formulations to laser-cut blade profiles, the future of table saw blades holds exciting possibilities for woodworkers seeking to push the boundaries of their craft.

Stay updated on industry trends and advancements to take advantage of the latest innovations in woodworking tools and technology and continue to push the limits of your creativity with the help of cutting-edge table saw blades.

Blade Compatibility: Understanding Table Saw Blades Across Different Saws

Exploring Blade Compatibility: Understanding How Table Saw Blades Work Across Various Saws

When delving into the realm of table saw blades, it’s essential to consider their compatibility with other types of saws, such as miter or circular saws. While table saw blades are primarily crafted for use with table saws, it’s worth noting that certain blades may also function effectively with alternative saw models like miter saws or circular saws.

However, before diving into your cutting projects, it’s paramount to verify the specifications and compatibility of the blade with your specific saw model.

Furthermore, shedding light on the disparities between table saw blades and those tailored for miter or circular saws can offer invaluable clarity, especially for woodworking novices or DIY enthusiasts.

By grasping the distinct attributes and applications of each blade type, you can then confidently discern the ideal tool for their precise cutting requirements, whether it involves rip cuts, crosscuts, bevel cuts, or specialized joinery.

Conclusion

In conclusion, table saw blades are indispensable tools for woodworkers of all skill levels, offering precision, versatility, and efficiency in cutting various materials. By delving into the types, sizes, and materials used in table saw blades, woodworkers can make informed decisions that enhance the quality of their projects.

As you embark on your woodworking journey, remember to prioritize safety and maintenance to ensure the longevity of your table saw blades. Regularly inspecting, cleaning, and sharpening your blades will not only improve their performance but also contribute to a safer working environment.

Whether you’re a seasoned professional or a novice enthusiast, exploring the diverse range of table saw blades available allows you to unleash your creativity and tackle projects with confidence. Experiment with different blade types, techniques, and materials to discover new possibilities and refine your craft.

In the ever-evolving landscape of woodworking tools and technologies, staying informed about industry trends and advancements is key to staying ahead of the curve. Embrace innovation, hone your skills, and enjoy the satisfaction of bringing your woodworking visions to life with precision and finesse.

While we’ve strived to cover a comprehensive range of topics regarding table saw blades, we understand that questions may still arise. If you find yourself seeking further clarification or have additional inquiries, feel free to leave a comment below.

We’re here to assist you in any way we can and ensure that you have all the information you need for your woodworking endeavors.

FAQs:

Difference between a rip blade and a crosscut blade:

Understand the distinctions between rip blades, ideal for cutting along the wood grain, and crosscut blades, designed for cutting across the grain.

Frequency of replacing table saw blades:

Table saw blades should be replaced when they become dull or damaged, varying based on usage and materials cut.

Compatibility of dado blades with any table saw:

Not all table saws are compatible with dado blades, so it’s crucial to check your saw’s specifications and safety guidelines before using one.

Value of investing in carbide-tipped blades:

Carbide-tipped blades are worth the investment for their durability and longevity, particularly suitable for cutting hardwoods and abrasive materials.

Methods for sharpening table saw blades:

Table saw blades can be sharpened using specialized blade sharpeners or by availing professional sharpening services.